Our team at the heart of a major energy innovation

We have just successfully completed a comprehensive technical and economic study for Hynamics (EDF Group) on the production of synthetic kerosene via methanolation. This strategic project aimed to assess the feasibility of a 30 kt/year e-kerosene production unit, using CO₂ and H₂ as feedstocks to produce methanol, followed by a ‘Methanol to Olefins to Jet’ conversion process.

A complete simulation of the base case

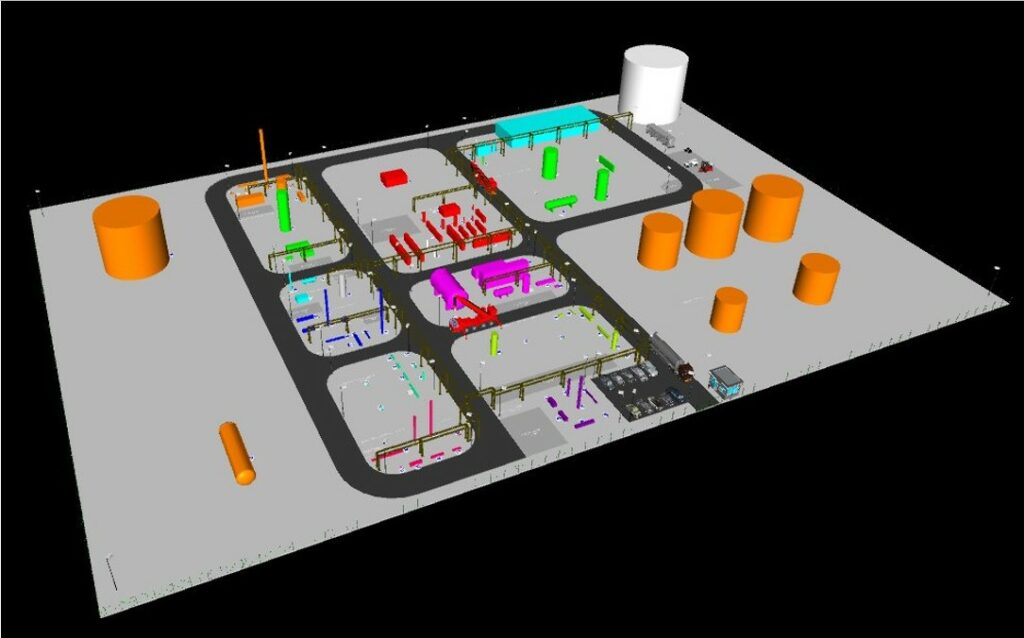

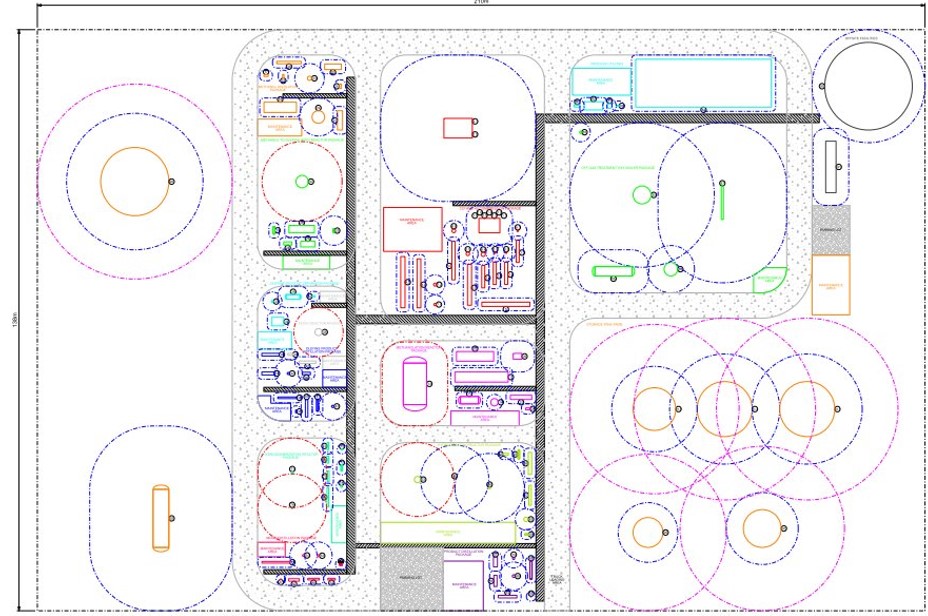

The team developed a base case (30 kt/year) including ASPEN, PFD and H&MB (Heat & Mass Balance) simulations, supplemented by a detailed layout and 3D model. This approach enabled an accurate assessment of capital expenditure (CAPEX) and operating expenditure (OPEX) costs.

The study also includes a reduced dimensioning scenario (15 kt/year) to assess potential economies of scale.

‘Working with Ekium has greatly helped us to better approach the production of e-SAF via MTJ. Ekium has proven expertise in the oil and gas sector, associated processes and decarbonisation solutions, enabling them to respond to complex project issues. Their flexibility and responsiveness are also key to the successful completion of this type of study.’

A technical challenge: modelling energy variability

One of the most innovative aspects of this study was the modelling of the plant’s operational variability according to three energy supply scenarios related to H₂ production:

1. Solar and wind renewable energy mix/grid: simulation of a supply combining renewable energies (solar and wind) with the grid

2. 100% renewable energy mix: scenario of complete autonomy in renewable energies

3. Balanced mix: optimisation between stability and environmental performance

These different scenarios made it possible to analyse the impact of energy variability on hydrogen production, a key element in the synthetic kerosene manufacturing process.

Our strengths

This project perfectly illustrates our distinctive skills:

- Our expertise in technical and economic analysis of synthetic fuels

- Our advanced skills in process modelling with ASPEN

- Our mastery of optimisation strategies to maximise product selectivity

- Our ability to accurately model the impact of energy variability on production costs.

What next?

This feasibility study could pave the way for future collaborations in the field of synthetic fuels, a strategic sector for the energy transition, particularly in aviation. It also strengthens our position as a leading partner for complex technical and economic studies in the energy sector.